Ferrous Sulfate Developer

Mixing a Ferrous Sulfate Developer

Here's a good general purpose ferrous sulfate developer for collodion. (and it's easy to remember!) The total volume is approximately 7.5 ounces.

- In an 500 ml beaker, Pour

- 210 ml Distilled Water

- 10 gm Ferrous Sulfate

- 10 ml Acetic Acid

- 10 ml Alcohol

And mix thoroughly until completely disolved, then filter the solution into an 8 ounce bottle.

To better understand what the developer is actually doing, and to make the recipe a little less mysterious, let's look at the function of each component and see what it does.

Water: the solvent.

The first ingredient is water. This is merely the solvent which allows the various chemicals to blend and provides a measure of dilution.

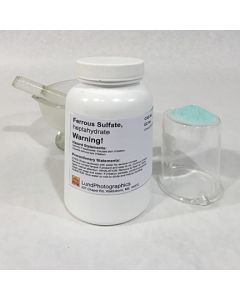

Ferrous Sulfate: the developer.

Next on the list is Ferrous Sulfate. This alone, is the developing (or reducing) agent. It acts to reduce the exposed silver halides (silver iodide & silver bromide) into metallic silver. If used by itself, without dilution or restraining, the image would develop uncontrollably fast, making developer flow lines and over development a serious problem.

Acetic Acid: the restrainer.

The speed of the developer can be slowed down or restrained by the addition of an acid. The usual choice for this is acetic acid, although other acids, such as nitric acid can also be used. Parenthetically, another commonly used restraining agent is sugar. And how does this work you ask? When dissolved into the developer, the sugar acts to thicken the fluid slightly, making it more viscous, slowing the motion of the chemistry that’s in solution, thereby slowing the rate at which the developer comes in contact with the exposed silver salts. If you'd like to see this concept in action, the next time you make a cup of hot tea, make two, one with sugar already dissolved in the water before inserting the tea bag, and the other with just water alone. You'll notice the tea using water alone gains color more quickly than the cup that had the sugar dissolved in it.

Alcohol: the wetting agent.

Finally, alcohol is added to the developer to act as a "wetting agent". The amount of alcohol can be adjusted as needed “on the fly”. If the developer has an oily appearance when poured on the plate, you definitely need to add more alcohol to the developer for the next plate. In my experience, it’s safer to err on the side of too much alcohol than too little.